PROJECT

Sliding Kortrijk’s station area into the future

10

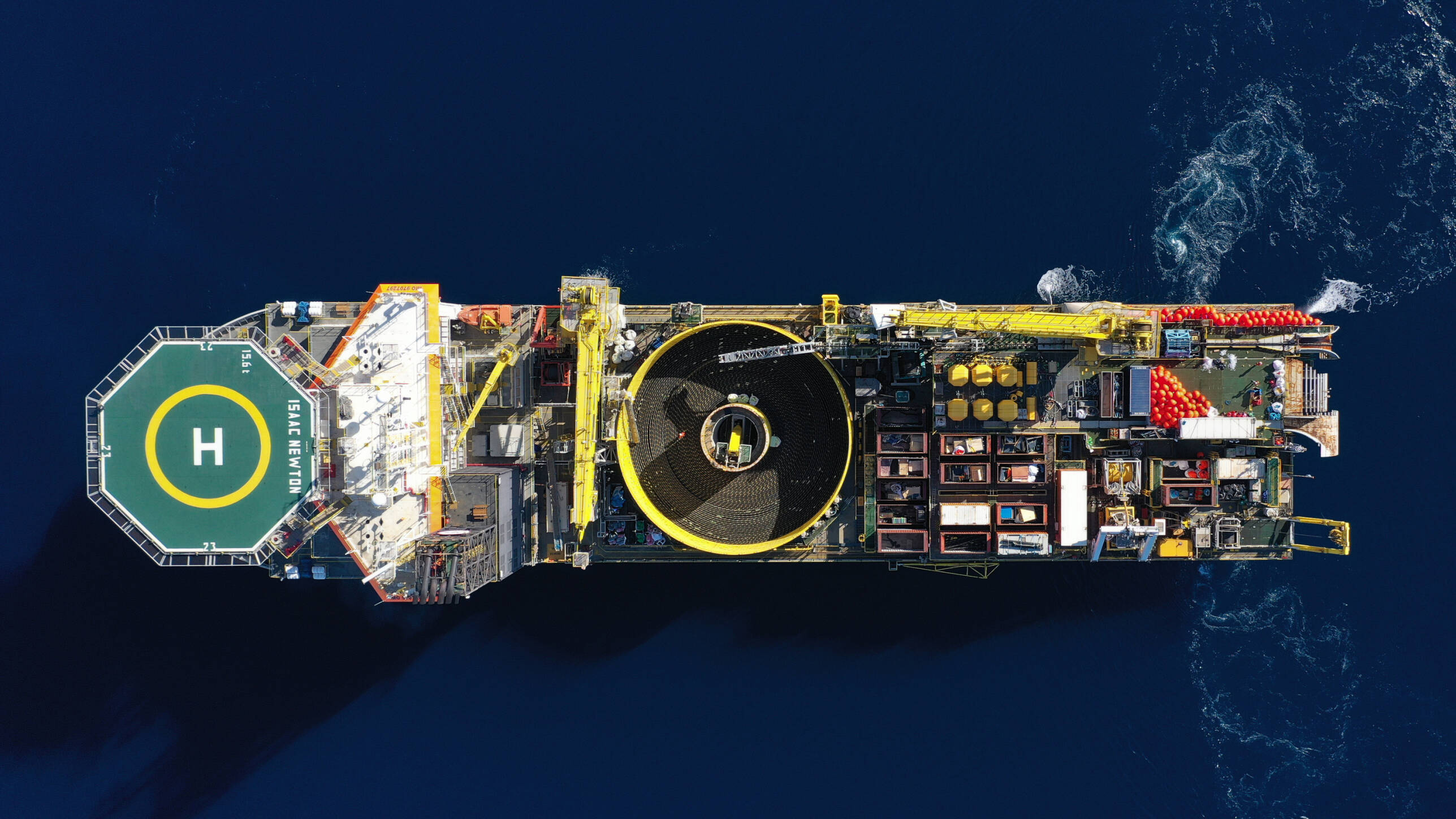

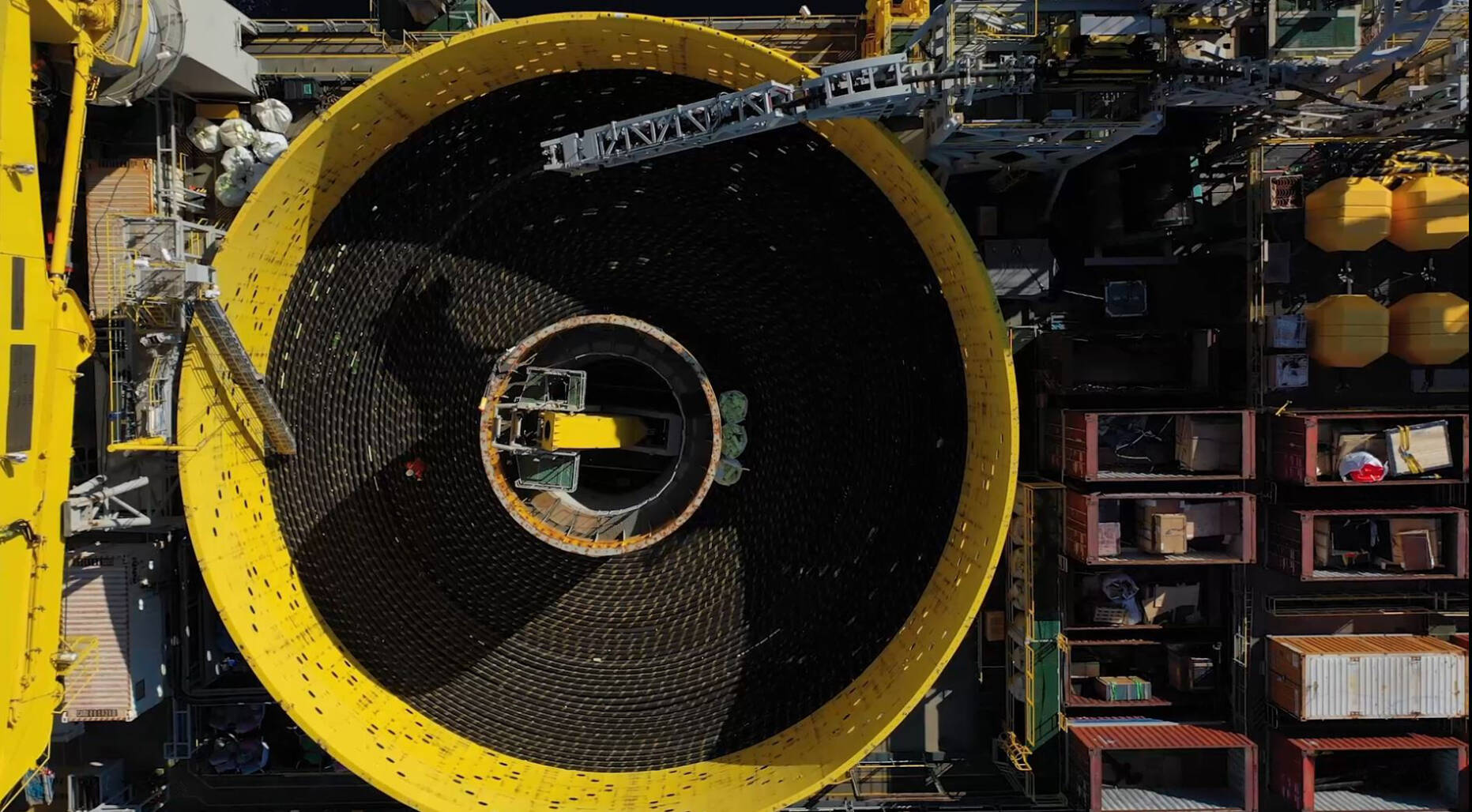

To lift and slide the tunnel into place,

10 concrete support blocks were provided.

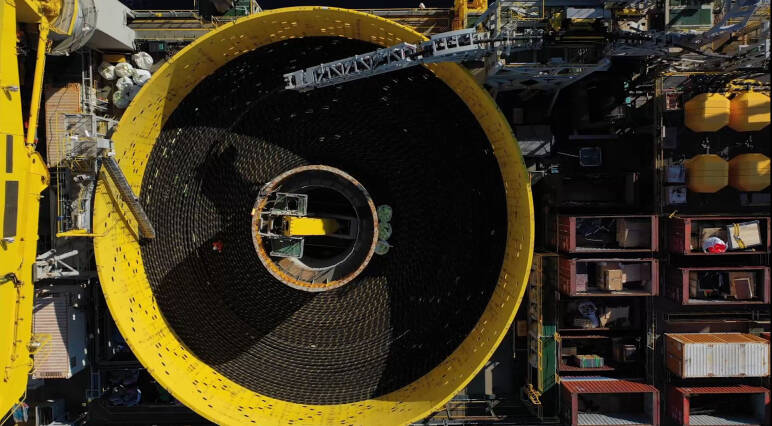

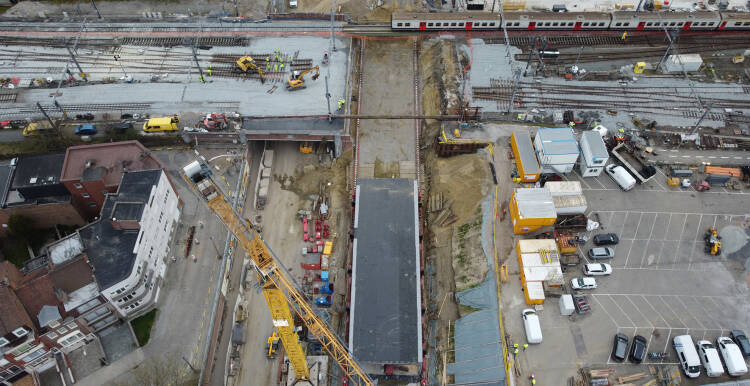

For this sliding operation, we built a section of the tunnel next to its final position, because the tracks under which this tunnel was placed could only be broken up for a very short time.

Weeks before the actual sliding operation, the prefab bus and bicycle tunnel was completed right next to the tracks. The result: a 35-metre and 1,350-tonne tunnel. Just before we slid the tunnel into place, Infrabel installed a temporary railway bridge and broke up all the other tracks. Only one track remained operational. We then excavated the soil under the former tracks to create an open building pit. After that, the team on site could jack up the tunnel, put it on rails and slowly slide it into place horizontally.

1,350 tonnes

The total weight of the tunnel is 1,350 tonnes

8 hours

The tunnel was finally slid into place in

8 hours time.

HOW DO YOU SLIDE A 35-METRE TUNNEL INTO PLACE?

Discover more infrastructure projects on our website.

Framework for the Kortrijk Station Project

This sliding operation is part of the Kortrijk Station Project, a partnership between the SNCB/NMBS, Infrabel, De Lijn, the city of Kortrijk, the Roads and Traffic Agency and Parko. Eurostation is the design agency. The total project will take about 10 years.

With this project, Kortrijk wants to transform the station area into a pleasant neighbourhood again, by optimizing the mobility for various road users. First of all, special attention is being paid to the needs of vulnerable road users (pedestrians and cyclists). Secondly, public transport is taken into account, and thirdly private transport. In this project, we built the bus and bicycle tunnel so that scheduled buses and cyclists can now pass through unhindered and completely safely.

The tunnel is

35 metres long,

12 metres wide and

6 metres high

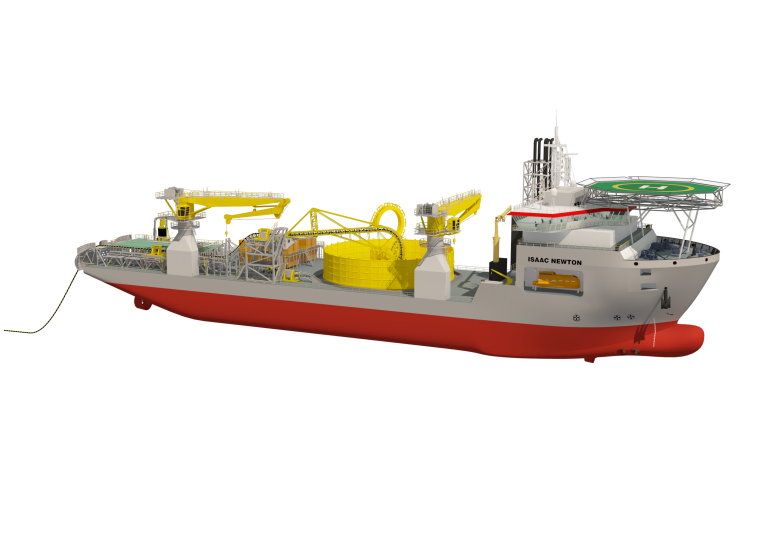

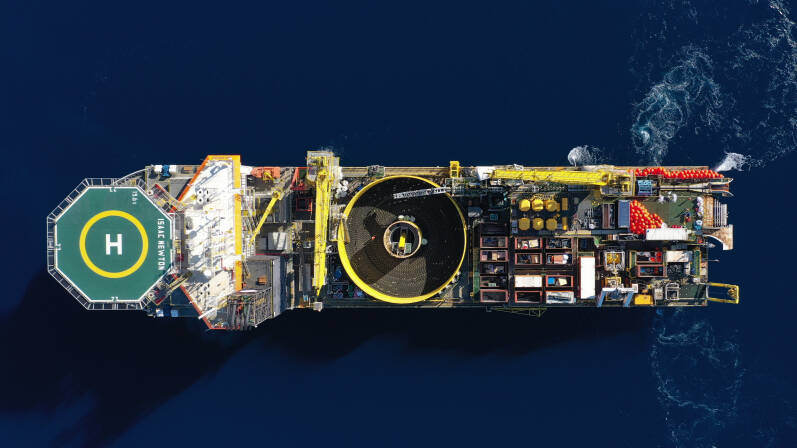

We already have a lot of experience with similar sliding operations, but the dimensions of this tunnel aren’t very common. In order to slide such a long tunnel on rails, it was supported by concrete blocks. When the tunnel was in its final position, we supplemented the earth around the tunnel and finished the tunnel on both sides.

Kenneth De Visch - Project manager civil works, takes you on a tour behind the scenes.

Wondering how we performed the works?

The Flemish city of Kortrijk has been developing sustainable projects for years within its ‘Kortrijk, climate city’ programme. One of the latest projects is the makeover of the station area. Kortrijk is redesigning and optimizing the neighbourhood to make more room for pedestrians, cyclists and public transport. Jan De Nul has just slid the new bus and bicycle tunnel into place, thus meeting the needs of the primary users perfectly: a safe and car-free connection between Kortrijk-Zuid and the city centre.

PROJECT

The Flemish city of Kortrijk has been developing sustainable projects for years within its ‘Kortrijk, climate city’ programme. One of the latest projects is the makeover of the station area. Kortrijk is redesigning and optimizing the neighbourhood to make more room for pedestrians, cyclists and public transport. Jan De Nul has just slid the new bus and bicycle tunnel into place, thus meeting the needs of the primary users perfectly: a safe and car-free connection between Kortrijk-Zuid and the city centre.

Kenneth De Visch - Project manager civil works, takes you on a tour behind the scenes.

Wondering how we did it?

We already have a lot of experience with similar sliding operations, but the dimensions of this tunnel aren’t very common. In order to slide such a long tunnel on rails, it was supported by concrete blocks. When the tunnel was in its final position, we supplemented the earth around the tunnel and finished the tunnel on both sides.

For this sliding operation, we built a section of the tunnel next to its final position, because the tracks under which this tunnel was placed could only be broken up for a very short time.

Weeks before the actual sliding operation, the prefab bus and bicycle tunnel was completed right next to the tracks. The result: a 35-metre and 1,350-tonne tunnel. Just before we slid the tunnel into place, Infrabel installed a temporary railway bridge and broke up all the other tracks. Only one track remained operational. We then excavated the soil under the former tracks to create an open building pit. After that, the team on site could jack up the tunnel, put it on rails and slowly slide it into place horizontally.

Discover more infrastructure projects on our website.

Framework for the Kortrijk Station Project

This sliding operation is part of the Kortrijk Station Project, a partnership between the SNCB/NMBS, Infrabel, De Lijn, the city of Kortrijk, the Roads and Traffic Agency and Parko. Eurostation is the design agency. The total project will take about 10 years.

With this project, Kortrijk wants to transform the station area into a pleasant neighbourhood again, by optimizing the mobility for various road users. First of all, special attention is being paid to the needs of vulnerable road users (pedestrians and cyclists). Secondly, public transport is taken into account, and thirdly private transport. In this project, we built the bus and bicycle tunnel so that scheduled buses and cyclists can now pass through unhindered and completely safely.

8 hours

The tunnel was finally slid into place in 8 hours time.

10

To lift and slide the tunnel into place, 10 concrete support blocks were provided.

1,350 tonnes

The total weight of the tunnel is 1,350 tonnes

The tunnel is

35 metres long,

12 metres wide and

6 metres high