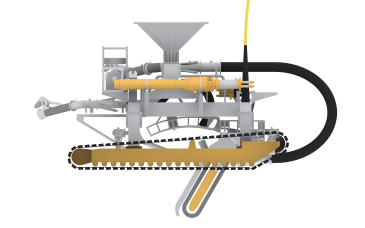

Green methanol is an efficient hydrogen carrier and proves to have one of the best energy densities of all alternative fuels. The single carbon atom allows for a clean combustion in engines. Standard engines on vessels can be adapted to handle methanol as a fuel. Dual fuel engines are already available that can work on both traditional fuels such as (bio)diesel and on methanol, depending on the availability in bunkering ports.

At the moment, more and more facilities are planned for the production of green methanol. But sustainable maritime works go much further than just transitioning to a renewable fuel. Constructors of vessels also implement other innovations, such as batteries that charge using recovered energy during operations, higher energy efficiency, and high-quality filtration systems. By combining all these aspects, maritime construction is making leaps and bounds towards a sustainable practice.

The most sustainable form, green methanol, comes from either biomass or green hydrogen, and is synthetised along with captured CO2 using renewable electricity. This means that, when this methanol is used as a fuel, we end up at almost carbon neutrality.

So-called blue methanol is produced using blue hydrogen in combination with carbon-capture technology, vastly reducing CO2 emissions, but still reliant on fossil fuels for its base production. This limits its ability to become fully sustainable.

Thanks to evolving technology, more sustainable production methods are available.

For the earliest industrial methods, methanol is produced with coal and natural gas as sources.

In a world grappling with the urgent need for a low environmental impact, the maritime industry finds itself at a crucial crossroads. As regulations tighten their grip, the quest for cleaner alternatives becomes paramount. Electric power may be reshaping land-based transport and equipment, a ship cannot be plugged in to charge her batteries on her way across the ocean. Other solutions with energy dense storage capacity on board are necessary. In the relentless pursuit of sustainability, a compelling contender emerges – green methanol.

Methanol has various advantages compared to other green fuels. Unlike hydrogen, it can be stored more easily and safely on board of a vessel. It doesn’t emit nitrogen oxides when burned, like in ammonia engines. In case of a leak, it easily dissolves in water and biodegrades quickly, so it poses less of a threat to the environment.

Of course, methanol as a fuel still brings a few challenges: Double the tank capacity is needed compared to a diesel-powered vessel for the same operation. And green methanol is not yet available everywhere.

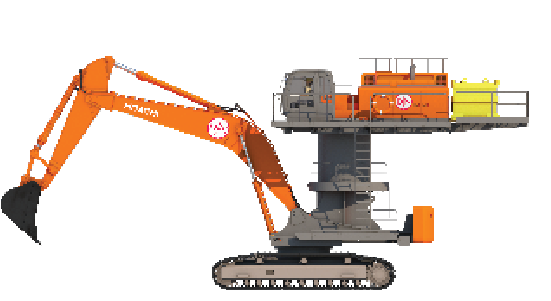

Jan De Nul has ordered a new cable-laying vessel, Fleeming Jenkin, with an unparalleled cable-carrying capacity of 28,000 tonnes. To make this vessel fit for the future, we have chosen to incorporate dual fuel engines that can work on methanol, for this we work together with ABC Engines. Add to this the ULEv-technology and these engines allow Fleeming Jenkin to work with extremely low emissions. And when green methanol is used, the vessel operates carbon-neutrally. This vessel will allow us to construct the energy transition in an even more sustainable way.

Early April, three vessels of that fleet, the Isaac Newton, Connector and Symphony, were docked together in the port of Zeebrugge. A perfect time to take a closer look at these three Red Giants.

This vessel will allow us to construct the energy transition in an even more sustainable way.

Visit jandenul.com and read more about the Fleeming Jenkin.

Visit jandenul.com and read more about the launching!

This vessel will allow us to construct the energy transition in an even more sustainable way.

Jan De Nul has ordered a new cable-laying vessel, Fleeming Jenkin, with an unparalleled cable-carrying capacity of 28,000 tonnes. To make this vessel fit for the future, we have chosen to incorporate dual fuel engines that can work on methanol, for this we work together with ABC Engines. Add to this the ULEv-technology and these engines allow Fleeming Jenkin to work with extremely low emissions. And when green methanol is used, the vessel operates carbon-neutrally. This vessel will allow us to construct the energy transition in an even more sustainable way.

At the moment, more and more facilities are planned for the production of green methanol. But sustainable maritime works go much further than just transitioning to a renewable fuel. Constructors of vessels also implement other innovations, such as batteries that charge using recovered energy during operations, higher energy efficiency, and high-quality filtration systems. By combining all these aspects, maritime construction is making leaps and bounds towards a sustainable practice.

The most sustainable form, green methanol, comes from either biomass or green hydrogen, and is synthetised along with captured CO2 using renewable electricity. This means that, when this methanol is used as a fuel, we end up at almost carbon neutrality.

Thanks to evolving technology, more sustainable production methods are available.

For the earliest industrial methods, methanol is produced with coal and natural gas as sources.

So-called blue methanol is produced using blue hydrogen in combination with carbon-capture technology, vastly reducing CO2 emissions, but still reliant on fossil fuels for its base production. This limits its ability to become fully sustainable.

Methanol has various advantages compared to other green fuels. Unlike hydrogen, it can be stored more easily and safely on board of a vessel. It doesn’t emit nitrogen oxides when burned, like in ammonia engines. In case of a leak, it easily dissolves in water and biodegrades quickly, so it poses less of a threat to the environment.

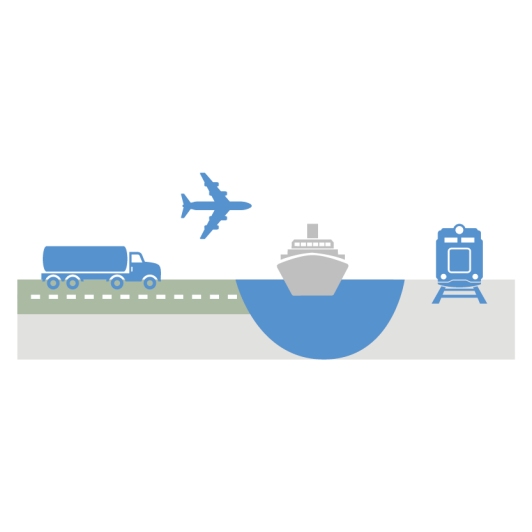

Of course, methanol as a fuel still brings a few challenges: Double the tank capacity is needed compared to a diesel-powered vessel for the same operation. And green methanol is not yet available everywhere.

Green methanol is an efficient hydrogen carrier and proves to have one of the best energy densities of all alternative fuels. The single carbon atom allows for a clean combustion in engines. Standard engines on vessels can be adapted to handle methanol as a fuel. Dual fuel engines are already available that can work on both traditional fuels such as (bio)diesel and on methanol, depending on the availability in bunkering ports.