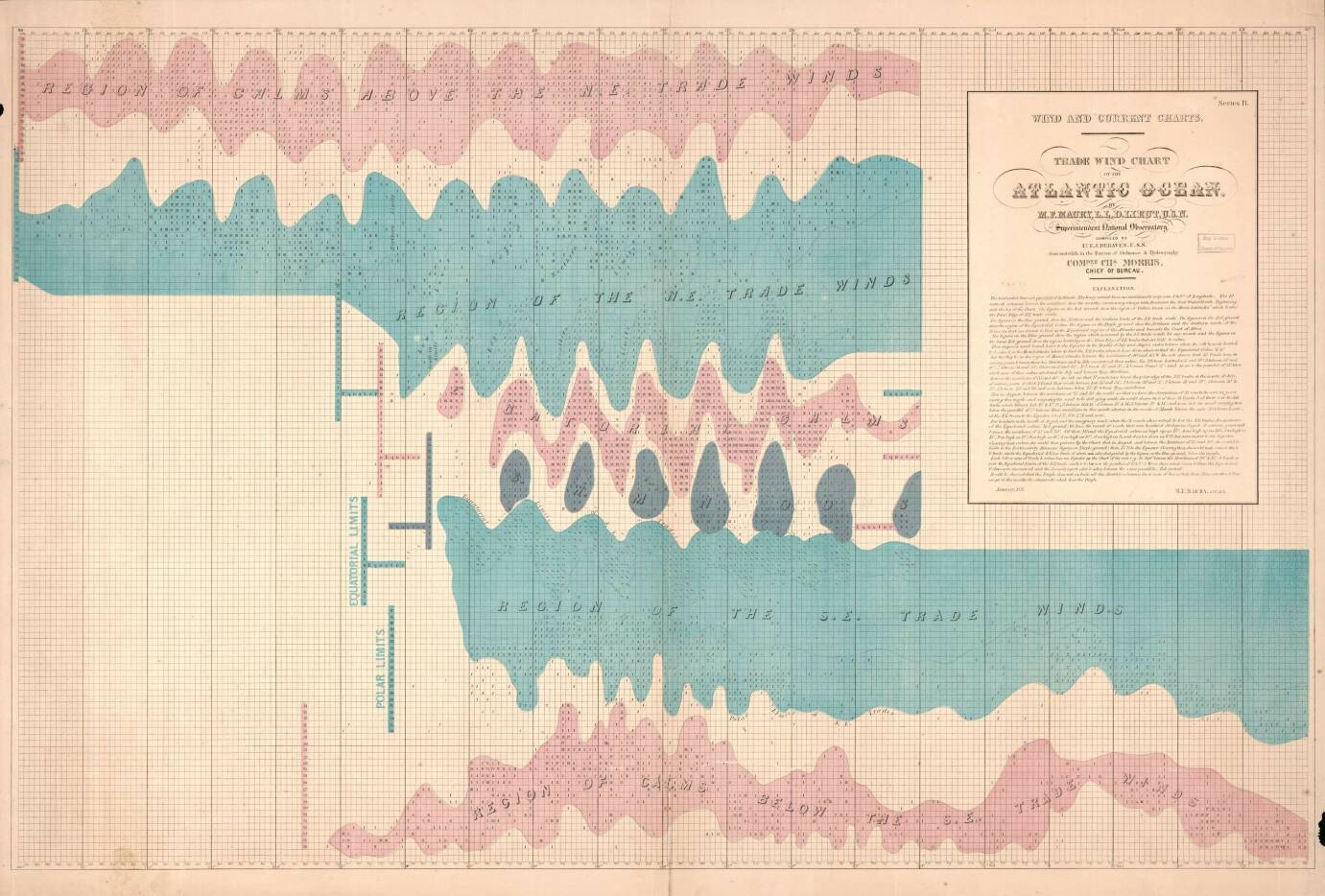

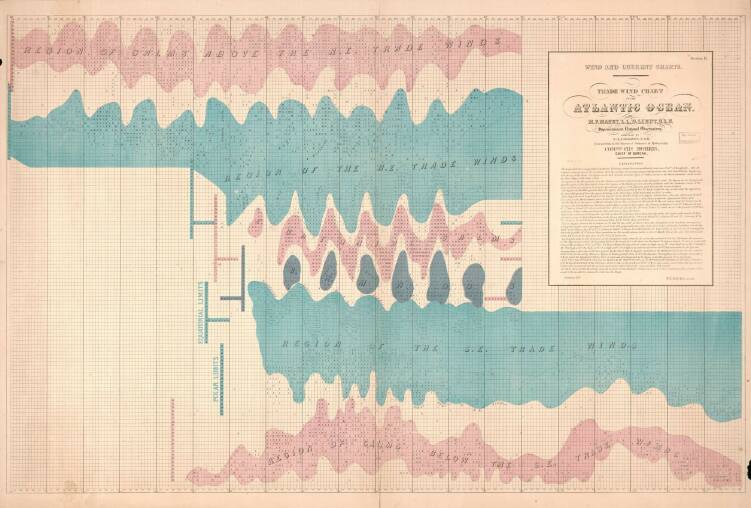

For centuries, people have been trading overseas without engines, but with thorough knowledge of nature, the seasons and the regular trade winds. In other words, they used the forces of nature as their energy source... renewable in the purest sense of the word. Now, if you know that “alizé” is French for “trade wind”, you will completely understand why the name “Les Alizés” is tailor-made for this innovative Offshore Installation Vessel.

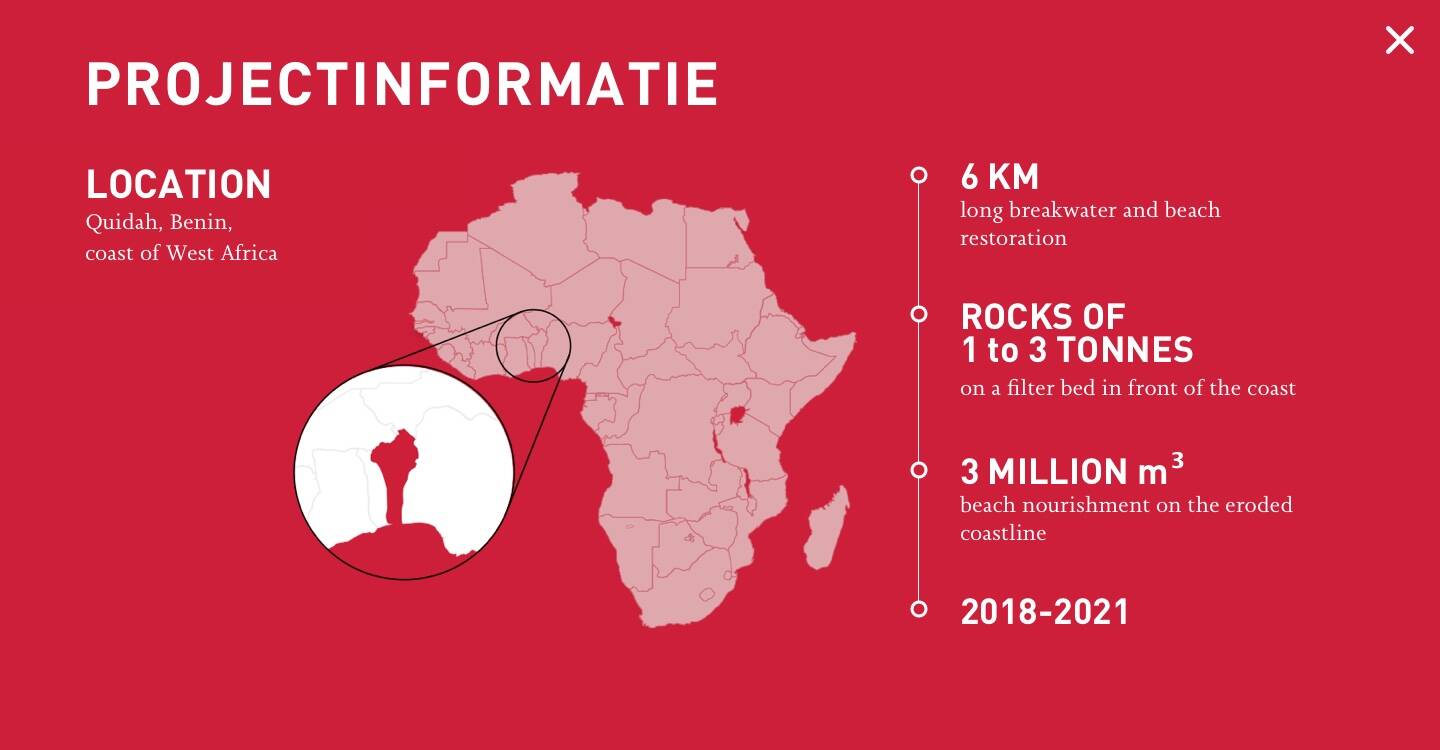

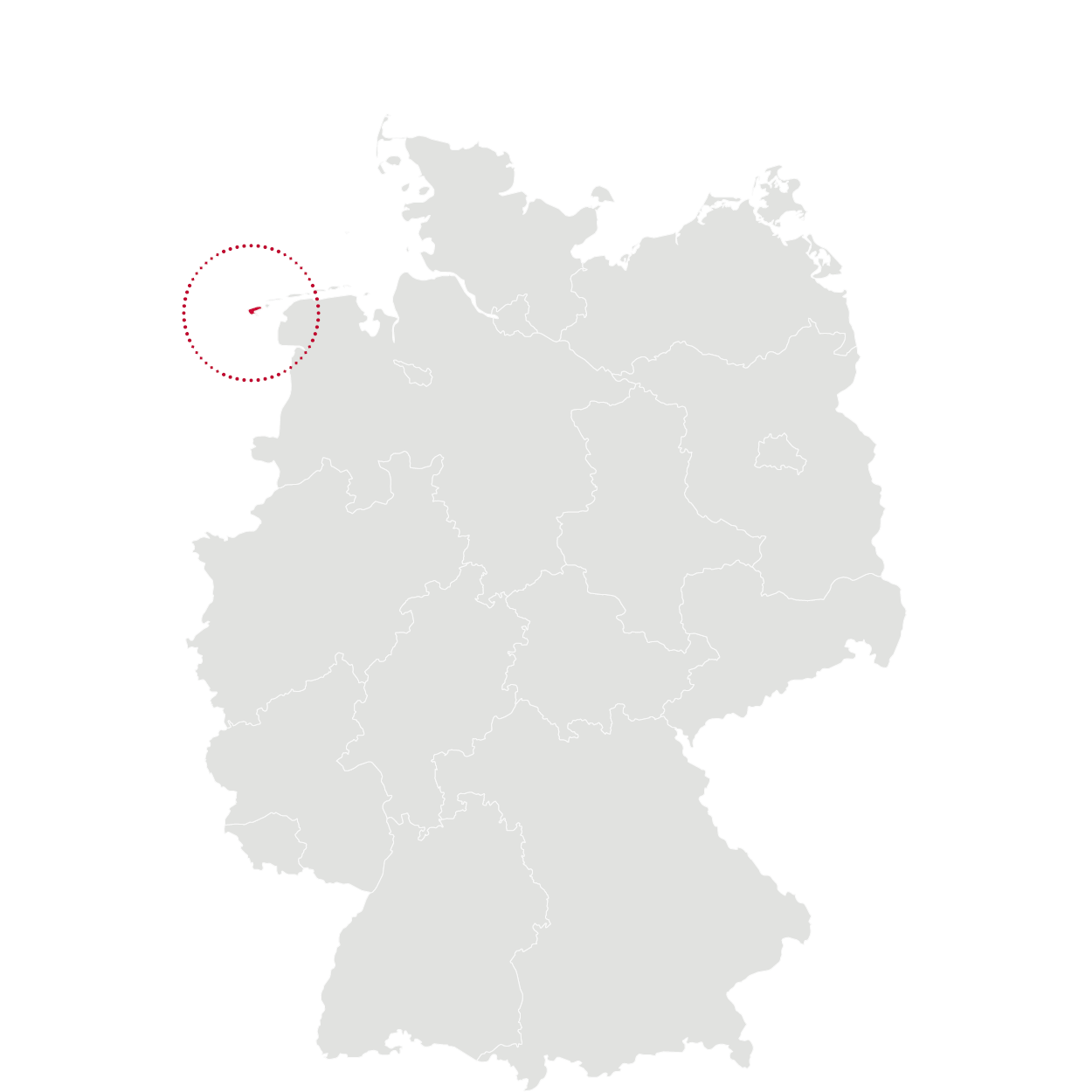

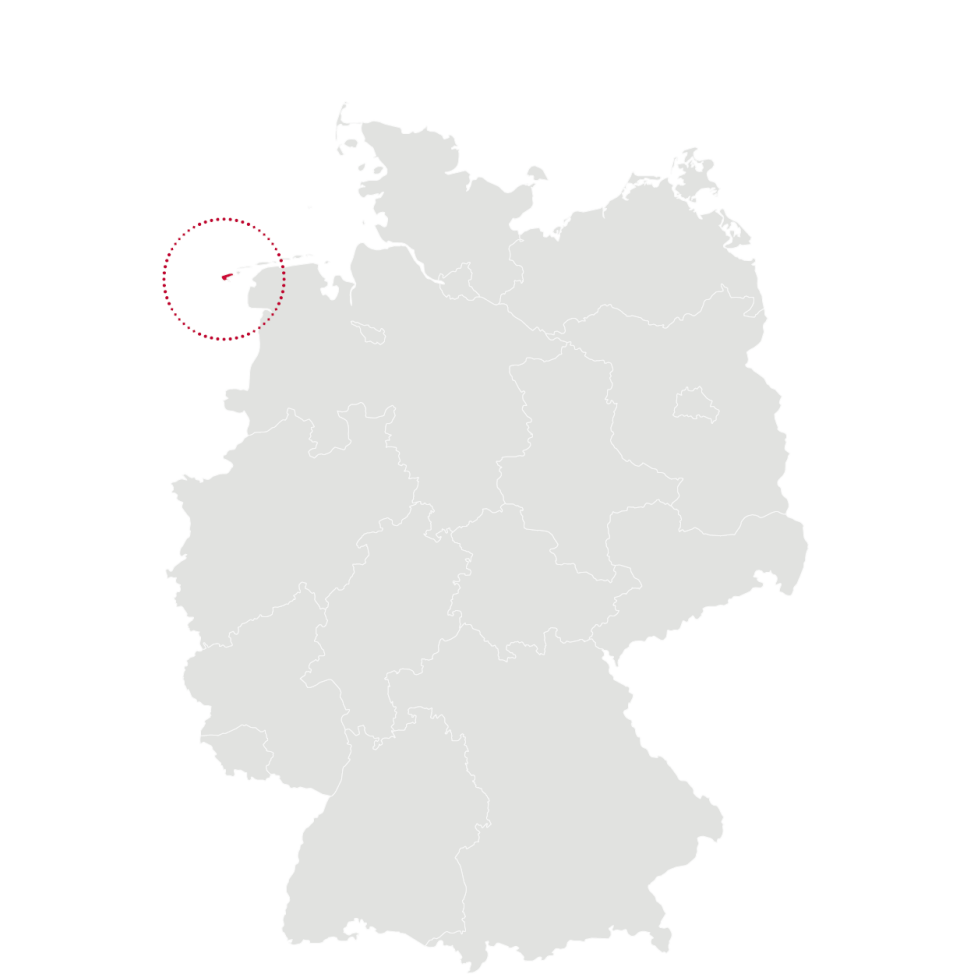

The Borkum Riffgrund 3 and Gode Wind 3 offshore wind farms for Ørsted Wind Power. For these wind farms, 107 monopile foundations will be installed in the German North Sea in 2023. A task perfectly suited to Les Alizés. Once completed, the wind farms will generate enough electricity to power approximately 1.2 million German households per year.

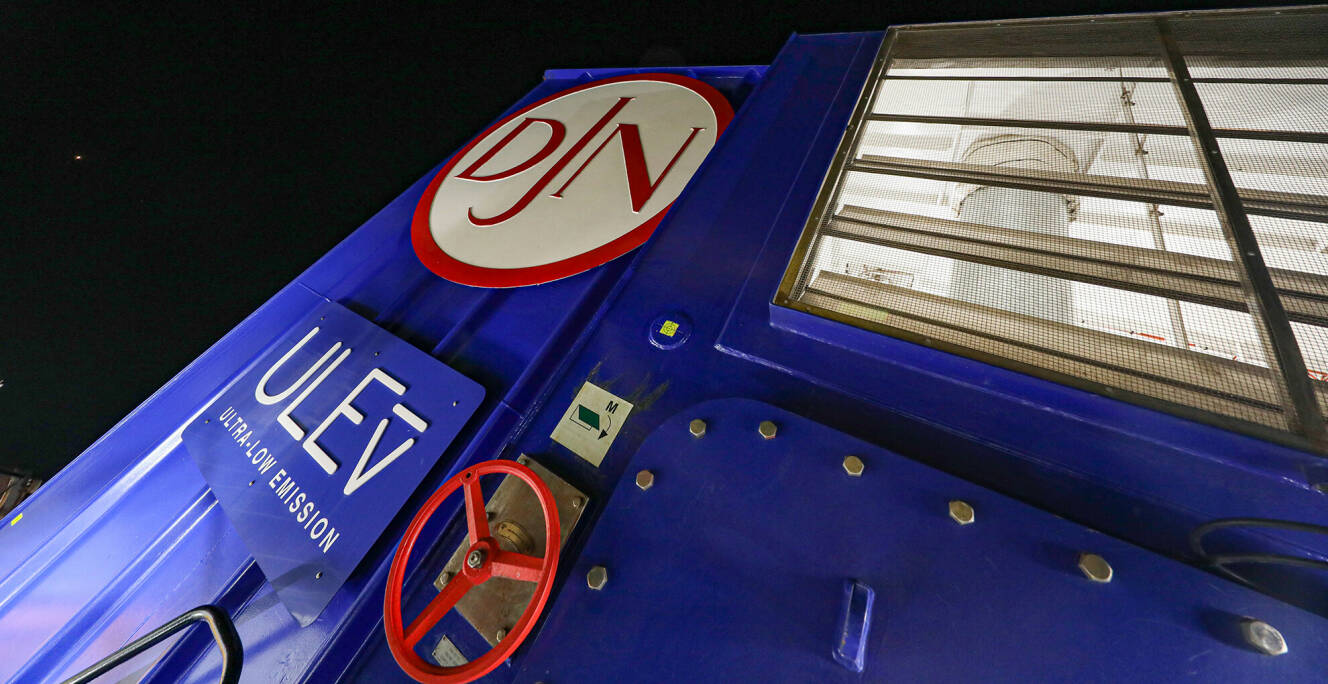

EU stage V standard

NOx Reduction

“Les Alizés is one of the first seaworthy installation vessels in the world with extremely low emissions, a so-called Ultra-Low Emission vessel or ULEv. In addition, we developed her power plant to be a hybrid setup combining diesel-driven generators with battery and drive technology. This will optimise her engine loading and recover potential energy returned from the heavy lift crane. On top of that, Les Alizés can also run on second-generation biodiesel. The result is a vessel that will not only enable green energy, but will partially run on it as well.”

Les Alizés is also known for her Green label. In what way was she developed with environmental consideration?

“On the one hand, the heave compensation system of the crane compensates for the vertical movements of the crane tip. On the other hand, we equipped Les Alizés with a motion-compensated monopile gripper. This is an advanced electrical gripper containing survey and guidance systems to compensate the gap between the moving vessel and the stationary world. Thanks to this, we can install the foundations with pinpoint accuracy, and guarantee our personnel’s safety at the same time.”

With a floating vessel that is constantly moving, how do you manage to install the foundations smoothly?

“For a Jack-Up Vessel like Voltaire, the maximum weight of her cargo is limited by the strength of her legs. In the case of a floating vessel like Les Alizés, it is her full floating capacity that is decisive for the weight of the cargo. As a result, she can transport and install more piles in one trip. Also, she can start installation works right away and does not need to spend time on jacking the hull out of the water, an operation that strongly depends on the actual soil conditions. These aspects make a floating vessel potentially more efficient for foundation installation works and allow her to operate where Jack-Up Vessels cannot. By contrast, a Jack-Up Vessel is less subject to sea fluctuations and slightly more stable to install higher components. So, it is fair to say that with Les Alizés and Voltaire we now have the perfect duo in our fleet for offshore wind farm installation.”

Unlike Voltaire, Les Alizés is a floating vessel. Why not develop a second jack-up?

“Wind turbines have only been getting bigger in recent years. Consequently, we need increasingly larger vessels to install them at sea. Les Alizés is one of the first vessels in the world capable of installing this newest generation of wind turbines. And with her immense deck space and heavy lift crane, she is also the first vessel of these dimensions in Jan De Nul’s fleet.”

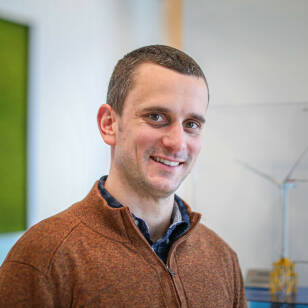

Gunter Servaes, Project Manager Vessel Construction

Complete realisation of the basic design:

a first for Jan De Nul for such a large vessel

Why the need to develop a vessel with these remarkable dimensions and power?

A lot can be said about this impressive piece of engineering. And no one better to reveal her secrets than Gunter Servaes, Project Manager Vessel Construction and one of the brains behind Les Alizés.

tonnes

Deck Space

Dead Weight Capacity

Breadth

Length Overall

More project news?

Check out our website.

A 5,000-tonne crane, a 61,000-tonne dead weight capacity and 9,300 m² of deck space. That is how you size a vessel to secure the green energy of tomorrow. Thanks to her dimensions and impressive lifting and loading capacities, Les Alizés is able to load out, transport and install multiple units of the largest and heaviest wind turbine foundations whilst floating. And she is also suitable to decommission offshore oil and gas platforms.

Imagine wind turbines more than 270 metres high with 120-metre blades, resting on foundations of up to 2,500 tonnes that need to be placed further out to sea than ever. Captures the imagination, doesn’t it? Yet it is not fantasy, but today’s reality. The rising demand for renewable energy makes us constantly push limits. And that is exactly what our Offshore Installation Vessel Les Alizés does best. After introducing you to our Jack-up Vessel Voltaire in our last edition of Focus, it’s time to devote a piece to Les Alizés, our newest Heavy-Lift Vessel capable of installing XXL offshore wind components.

For centuries, people have been trading overseas without engines, but with thorough knowledge of nature, the seasons and the regular trade winds. In other words, they used the forces of nature as their energy source... renewable in the purest sense of the word. Now, if you know that “alizé” is French for “trade wind”, you will completely understand why the name “Les Alizés” is tailor-made for this innovative Offshore Installation Vessel.

More project news?

Check out our website.

The Borkum Riffgrund 3 and Gode Wind 3 offshore wind farms for Ørsted Wind Power. For these wind farms, 107 monopile foundations will be installed in the German North Sea in 2023. A task perfectly suited to Les Alizés. Once completed, the wind farms will generate enough electricity to power approximately 1.2 million German households per year.

NOx Reduction

EU stage V standard

“Les Alizés is one of the first seaworthy installation vessels in the world with extremely low emissions, a so-called Ultra-Low Emission vessel or ULEv. In addition, we developed her power plant to be a hybrid setup combining diesel-driven generators with battery and drive technology. This will optimise her engine loading and recover potential energy returned from the heavy lift crane. On top of that, Les Alizés can also run on second-generation biodiesel. The result is a vessel that will not only enable green energy, but will partially run on it as well.”

Les Alizés is also known for her Green label. In what way was she developed with environmental consideration?

“On the one hand, the heave compensation system of the crane compensates for the vertical movements of the crane tip. On the other hand, we equipped Les Alizés with a motion-compensated monopile gripper. This is an advanced electrical gripper containing survey and guidance systems to compensate the gap between the moving vessel and the stationary world. Thanks to this, we can install the foundations with pinpoint accuracy, and guarantee our personnel’s safety at the same time.”

With a floating vessel that is constantly moving, how do you manage to install the foundations smoothly?

“For a Jack-Up Vessel like Voltaire, the maximum weight of her cargo is limited by the strength of her legs. In the case of a floating vessel like Les Alizés, it is her full floating capacity that is decisive for the weight of the cargo. As a result, she can transport and install more piles in one trip. Also, she can start installation works right away and does not need to spend time on jacking the hull out of the water, an operation that strongly depends on the actual soil conditions. These aspects make a floating vessel potentially more efficient for foundation installation works and allow her to operate where Jack-Up Vessels cannot. By contrast, a Jack-Up Vessel is less subject to sea fluctuations and slightly more stable to install higher components. So, it is fair to say that with Les Alizés and Voltaire we now have the perfect duo in our fleet for offshore wind farm installation.”

Unlike Voltaire, Les Alizés is a floating vessel. Why not develop a second jack-up?

“Wind turbines have only been getting bigger in recent years. Consequently, we need increasingly larger vessels to install them at sea. Les Alizés is one of the first vessels in the world capable of installing this newest generation of wind turbines. And with her immense deck space and heavy lift crane, she is also the first vessel of these dimensions in Jan De Nul’s fleet.”

Why the need to develop a vessel with these remarkable dimensions and power?

A lot can be said about this impressive piece of engineering. And no one better to reveal her secrets than Gunter Servaes, Project Manager Vessel Construction and one of the brains behind Les Alizés.

Gunter Servaes, Project Manager Vessel Construction

Complete realisation of the basic design:

a first for Jan De Nul for such a large vessel

Deck Space

Dead Weight Capacity

Breadth

Length Overall

tonnes

A 5,000-tonne crane, a 61,000-tonne dead weight capacity and 9,300 m² of deck space. That is how you size a vessel to secure the green energy of tomorrow. Thanks to her dimensions and impressive lifting and loading capacities, Les Alizés is able to load out, transport and install multiple units of the largest and heaviest wind turbine foundations whilst floating. And she is also suitable to decommission offshore oil and gas platforms.

Imagine wind turbines more than 270 metres high with 120-metre blades, resting on foundations of up to 2,500 tonnes that need to be placed further out to sea than ever. Captures the imagination, doesn’t it? Yet it is not fantasy, but today’s reality. The rising demand for renewable energy makes us constantly push limits. And that is exactly what our Offshore Installation Vessel Les Alizés does best. After introducing you to our Jack-up Vessel Voltaire in our last edition of Focus, it’s time to devote a piece to Les Alizés, our newest Heavy-Lift Vessel capable of installing XXL offshore wind components.