The Swordfish is completely designed to our needs. It is a welcome addition and perfect companion to our other in-house built intertidal vehicles Sunfish, Moonfish and Starfishes. These trenchers have already proven their immense value in several cable protection projects, each time being precisely adapted to the project at hand. With its 500 metres depth capability, the Swordfish is the deepest diver of the family. In line with their operation zones, both the Moonfish and Swordfish are launched from a support vessel and are controlled remotely through use of an umbilical. In turn, the Sunfish and Starfish work independently with the operator on board.

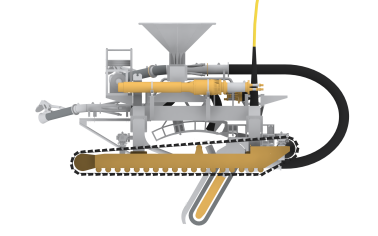

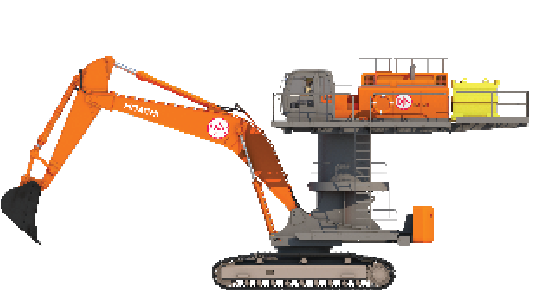

Intertidal Trenching Vehicle in jetting mode

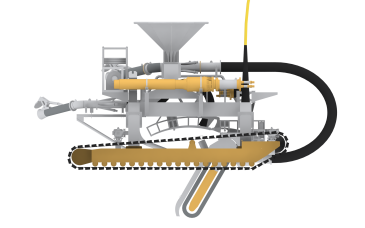

Ploughing Vehicle

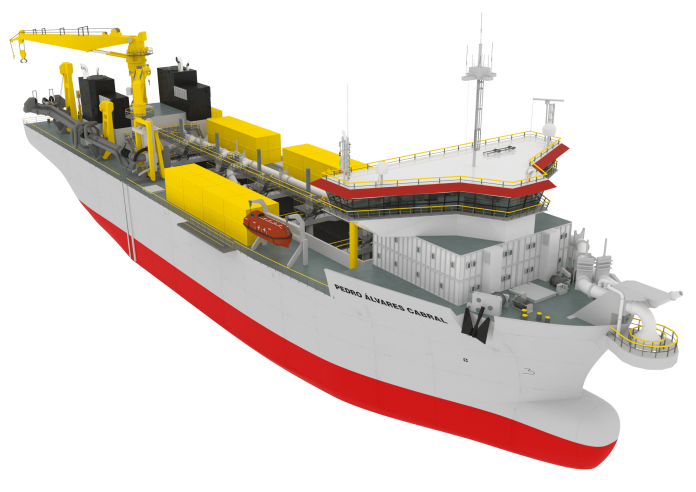

The Swordfish is specially designed to work offshore, so it needs a home base to launch and control it in these deeper waters. It is the Symphony, our recently acquired Offshore Support Vessel, that will house the trencher. With a custom-made A-frame, the Swordfish is launched in the water from the vessel to the bottom of the sea. Through an umbilical of 800 metres long, it stays connected to the Symphony, which allows to remotely operate the trencher from a control room on board of the vessel.

When we say the Swordfish is a multi-purpose trencher, it is for a reason. The vehicle can be equipped in two configuration modes:

Thanks to these two configurations, the high-powered Swordfish can be equipped to work on a wide range of soil types. Neither the softest soil nor the hardest clay thus pose an obstacle to our latest trencher.

What doesn’t change between either of the configurations, is the care with which the Swordfish buries the cable. The vehicle has innovative cable handling and sophisticated load sensing systems to prevent damaging the cable.

More technical details?

Check out our website.

The Swordfish, an excellent example of versatility

The Swordfish is a real gamechanger. This multi-purpose trencher defies a wide range of soils to bury cables safely in waters up to 500 metres deep. At Jan De Nul, overcoming challenges with creativity is what we do best. And the Swordfish is once again excellent proof that our in-house knowledge and skills perfectly lend themselves to that. With its ability to operate offshore and its easily customisable configuration, the Swordfish is a logical addition to our existing collection of trenchers. This family of ‘Fishes’ buries cables in diverse soils, from land to deep sea.

Everyone, from the largest multinational to the smallest household, is looking for reliable, affordable and renewable energy. Inevitably, as demand spikes, supply needs to follow suit. In other words, we need to rapidly expand our green energy production. Where do we do that? As availability of space on land is limited, offshore wind farms are booming. Unfortunately, the number of machines and equipment that are apt to build these much-needed wind farms is still low. The challenge gets even bigger further out at sea, since deep waters and complex soils make it impossible to build high-quality energy solutions.

Tim De Munter, Trenching Superintendent

Tom Baguet, Operations Support Manager Offshore

More technical details?

Check out our website.

Tim De Munter, Trenching Superintendent

Tom Baguet, Operations Support Manager Offshore

The Swordfish is completely designed to our needs. It is a welcome addition and perfect companion to our other in-house built intertidal vehicles Sunfish, Moonfish and Starfishes. These trenchers have already proven their immense value in several cable protection projects, each time being precisely adapted to the project at hand. With its 500 metres depth capability, the Swordfish is the deepest diver of the family. In line with their operation zones, both the Moonfish and Swordfish are launched from a support vessel and are controlled remotely through use of an umbilical. In turn, the Sunfish and Starfish work independently with the operator on board.

Intertidal Trenching Vehicle in jetting mode

Ploughing Vehicle

The Swordfish is specially designed to work offshore, so it needs a home base to launch and control it in these deeper waters. It is the Symphony, our recently acquired Offshore Support Vessel, that will house the trencher. With a custom-made A-frame, the Swordfish is launched in the water from the vessel to the bottom of the sea. Through an umbilical of 800 metres long, it stays connected to the Symphony, which allows to remotely operate the trencher from a control room on board of the vessel.

Thanks to these two configurations, the high-powered Swordfish can be equipped to work on a wide range of soil types. Neither the softest soil nor the hardest clay thus pose an obstacle to our latest trencher.

What doesn’t change between either of the configurations, is the care with which the Swordfish buries the cable. The vehicle has innovative cable handling and sophisticated load sensing systems to prevent damaging the cable.

When we say the Swordfish is a multi-purpose trencher, it is for a reason. The vehicle can be equipped in two configuration modes:

The Swordfish, an excellent example of versatility

The Swordfish is a real gamechanger. This multi-purpose trencher defies a wide range of soils to bury cables safely in waters up to 500 metres deep. At Jan De Nul, overcoming challenges with creativity is what we do best. And the Swordfish is once again excellent proof that our in-house knowledge and skills perfectly lend themselves to that. With its ability to operate offshore and its easily customisable configuration, the Swordfish is a logical addition to our existing collection of trenchers. This family of ‘Fishes’ buries cables in diverse soils, from land to deep sea.

Everyone, from the largest multinational to the smallest household, is looking for reliable, affordable and renewable energy. Inevitably, as demand spikes, supply needs to follow suit. In other words, we need to rapidly expand our green energy production. Where do we do that? As availability of space on land is limited, offshore wind farms are booming. Unfortunately, the number of machines and equipment that are apt to build these much-needed wind farms is still low. The challenge gets even bigger further out at sea, since deep waters and complex soils make it impossible to build high-quality energy solutions.