PFAS are just one category of soil and water contaminants. There are many other possible culprits, such as petrochemical contaminants. In that case, and if the structure of the soil allows for it, Envisan prioritises on-site biopiling.

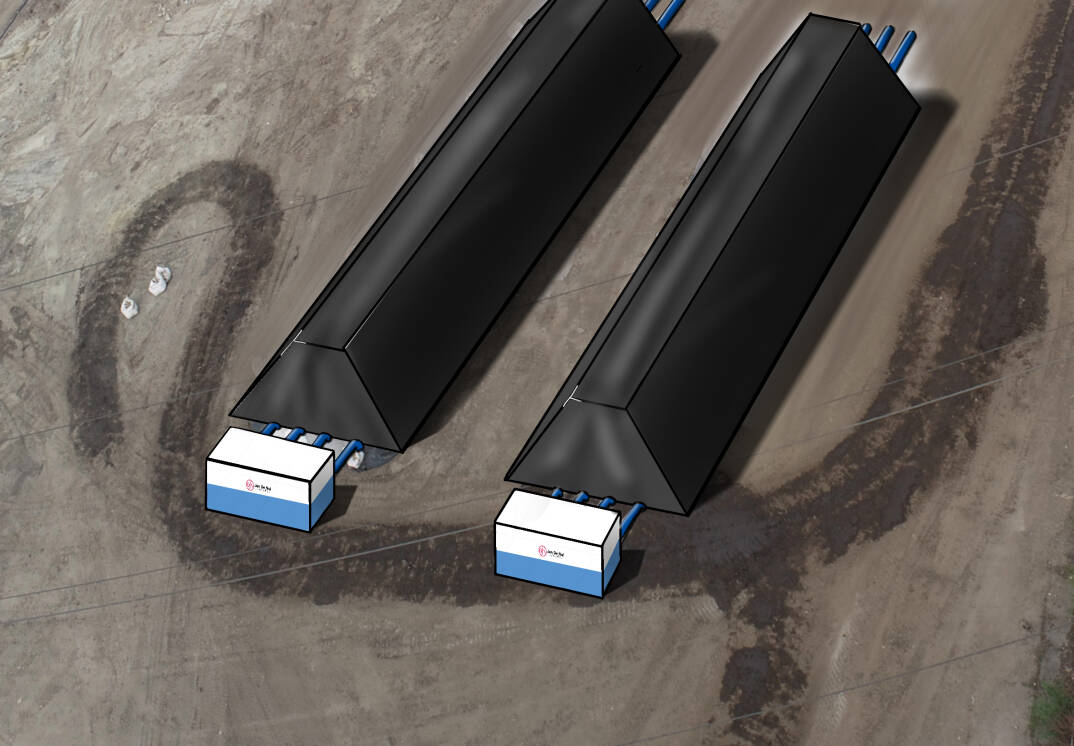

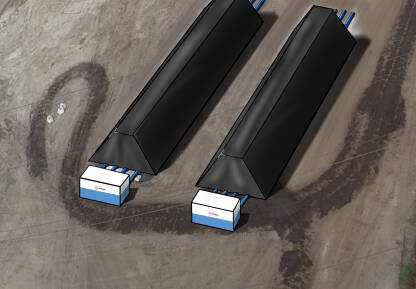

This technique involves assembling the contaminated soils into compost piles, after which they are enclosed for treatment. Micro-organisms then break down the contamination into less harmful forms. The extracted air from the biopiles is collected and purified via a biofilter, sometimes combined with a catalytic afterburner. Envisan recovers the heat released in this process to raise the temperature in the biopiles.

Biopiling: letting nature work its magic

Soil washing scores top for cost efficiency

Today, soil washing or physicochemical treatment is the go-to option to combat heavily polluted PFAS sites. The technique consists of a series of washing and separation processes. In the end, over 80% of an average polluted soil is turned into PFAS-free coarse sand, which can be reused in various civil applications. And what about the process water? Well, that water is first reused for numerous washing cycles, after which it gets completely purified and released in the environment. Only the contaminated fine fraction, less than 20% for an average soil, has to be processed further. In many cases, it is landfilled in line with European legislation.

Pieterjan Waeyaert, Project Manager Environmental Works

Kris Dendoncker, Project Manager Environmental Works

We’re not only going for more efficient, but also for more sustainable. Our goal is to make carbon-neutral soil and groundwater remediation possible for organisations. To give you an idea: we strictly use green energy on project sites. Heck, we might even show up with a hydrogen-fueled crane. Most governments and large enterprises have set ambitious climate goals, and we pull out all the stops to help them achieve these goals – one sustainable PFAS remediation at a time.

Did you know that our soil-washing installations are mobile? That means we can remediate your PFAS-polluted soil on site. In other words, we eliminate transport to treatment centers, resulting in a drastic reduction of CO2 emissions and less heavy mobility around your yard. If legislation and procedures are on our side, we go wherever you need us to be.

In-house R&D as the driving force

“There are other techniques to remediate PFAS-polluted soil but these are still in the research phase and are simply not scalable, sustainable or financially feasible at the moment. We’re keeping a close eye on some promising technologies in the drinking water industry, such as nanofiltration and reverse osmosis, or even new technologies based on advanced oxidation. But for now, we focus on optimising the soil washing treatment. With success: our R&D team managed to significantly increase the efficiency of our soil-washing installations in France and Belgium. To illustrate, we’re now able to extract 95 to 99% of PFAS from the coarse sand. And we’ll keep on investing in our R&D to provide owners of contaminated land with even more efficient solutions in the future.”

PFAS explained

Our valorisation centre at Île Monsin in action

Fighting the good fight since 1992

“As a specialist in soil and groundwater remediation, Envisan has been studying emerging contaminants since its foundation in 1992. Our own R&D team conducts most of the research, but we also regularly partner up with universities and other institutions. Needless to say, PFAS have been at the center of our attention for quite a while. It’s only in recent years that most people have first heard of these so-called forever chemicals, but their health risks have been known for much longer. At Envisan, we’ve been testing several techniques to remediate PFAS in soil and water since 2016 – innovative as well as more traditional techniques. And the available results all point in the same direction: soil washing.”

From US drinking water to the soil in Europe and even the Arctic snow, more and more info is surfacing on the alarming levels of PFAS chemicals in our environment. Consequently, many public and private organisations have come to realise that they own toxic land. And the matter becomes even more pressing when they have major civil engineering or marine projects in mind. How do you handle enormous volumes of polluted soil without putting public health in danger? Envisan, the environmental division of Jan De Nul, worked out an effective solution – which is more circular than you’d think.

PFAS are just one category of soil and water contaminants. There are many other possible culprits, such as petrochemical contaminants. In that case, and if the structure of the soil allows for it, Envisan prioritises on-site biopiling.

This technique involves assembling the contaminated soils into compost piles, after which they are enclosed for treatment. Micro-organisms then break down the contamination into less harmful forms. The extracted air from the biopiles is collected and purified via a biofilter, sometimes combined with a catalytic afterburner. Envisan recovers the heat released in this process to raise the temperature in the biopiles.

Biopiling: letting nature work its magic

We’re not only going for more efficient, but also for more sustainable. Our goal is to make carbon-neutral soil and groundwater remediation possible for organisations. To give you an idea: we strictly use green energy on project sites. Heck, we might even show up with a hydrogen-fueled crane. Most governments and large enterprises have set ambitious climate goals, and we pull out all the stops to help them achieve these goals – one sustainable PFAS remediation at a time.

Did you know that our soil-washing installations are mobile? That means we can remediate your PFAS-polluted soil on site. In other words, we eliminate transport to treatment centers, resulting in a drastic reduction of CO2 emissions and less heavy mobility around your yard. If legislation and procedures are on our side, we go wherever you need us to be.

“There are other techniques to remediate PFAS-polluted soil but these are still in the research phase and are simply not scalable, sustainable or financially feasible at the moment. We’re keeping a close eye on some promising technologies in the drinking water industry, such as nanofiltration and reverse osmosis, or even new technologies based on advanced oxidation. But for now, we focus on optimising the soil washing treatment. With success: our R&D team managed to significantly increase the efficiency of our soil-washing installations in France and Belgium. To illustrate, we’re now able to extract 95 to 99% of PFAS from the coarse sand. And we’ll keep on investing in our R&D to provide owners of contaminated land with even more efficient solutions in the future.”

In-house R&D as the driving force

Today, soil washing or physicochemical treatment is the go-to option to combat heavily polluted PFAS sites. The technique consists of a series of washing and separation processes. In the end, over 80% of an average polluted soil is turned into PFAS-free coarse sand, which can be reused in various civil applications. And what about the process water? Well, that water is first reused for numerous washing cycles, after which it gets completely purified and released in the environment. Only the contaminated fine fraction, less than 20% for an average soil, has to be processed further. In many cases, it is landfilled in line with European legislation.

Soil washing scores top for cost efficiency

“As a specialist in soil and groundwater remediation, Envisan has been studying emerging contaminants since its foundation in 1992. Our own R&D team conducts most of the research, but we also regularly partner up with universities and other institutions. Needless to say, PFAS have been at the center of our attention for quite a while. It’s only in recent years that most people have first heard of these so-called forever chemicals, but their health risks have been known for much longer. At Envisan, we’ve been testing several techniques to remediate PFAS in soil and water since 2016 – innovative as well as more traditional techniques. And the available results all point in the same direction: soil washing.”

Fighting the good fight since 1992

Pieterjan Waeyaert, Project Manager Environmental Works

Kris Dendoncker, Project Manager Environmental Works

Our valorisation centre at Île Monsin in action

The production and use of PFAS has been heavily restricted in recent decades. Many governments, including Europe, work towards a full ban on PFAS unless they’re essential to society (e.g. medical equipment).

High levels of PFAS in our body can lead to adverse health effects, including decreased fertility, behavioral changes, increased risk of some cancers, and higher cholesterol levels.

Exposure happens when a person breathes, eats or drinks a chemical. For example, people may be exposed by eating food grown or raised in PFAS-contaminated soil or water, including agricultural products, wild game, and fish.

The carbon-fluorine bond that gives PFAS their useful properties is one of the strongest ever created in organic chemistry. The result: these chemicals barely degrade in the environment (or in our body).

Because of the chemicals’ unequaled resistance to moisture, heat and stains, you find them in many everyday items, such as carpet, cleaning products, paint, packaging and cookware.

PFAS, short for poly and perfluoroalkyl substances, is a class of more than 4,000 different chemicals, of which PFOS and PFOA are the most commonly used and widespread.

From US drinking water to the soil in Europe and even the Arctic snow, more and more info is surfacing on the alarming levels of PFAS chemicals in our environment. Consequently, many public and private organisations have come to realise that they own toxic land. And the matter becomes even more pressing when they have major civil engineering or marine projects in mind. How do you handle enormous volumes of polluted soil without putting public health in danger? Envisan, the environmental division of Jan De Nul, worked out an effective solution – which is more circular than you’d think.

Installation

24 h

Ostend – Nieuwpoort

6 h

Kallo – Ostend

12 h