Impossible made possible

More details?

Check out our project summary.

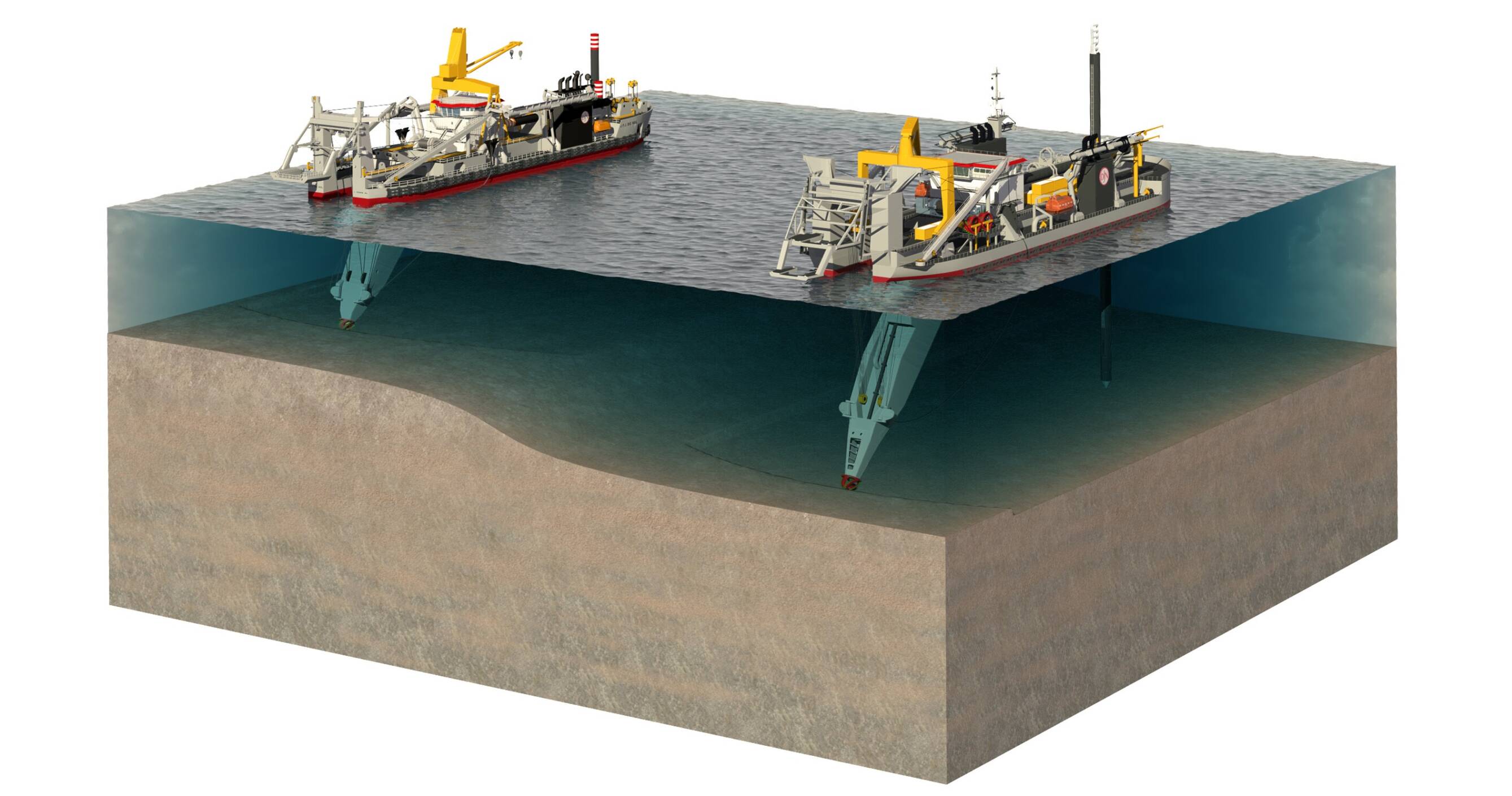

In the event of higher swells or waves, dredging works with a cutter are negatively affected, because the spud and the cutterhead have to remain in the same position at all times. By making some unique adjustments to the spud carrier and the flexible suspension of the cutter ladder of the Willem van Rubroeck, we ensured that more movements on the vessel’s structure are allowed and vibrations are absorbed, so that it can continue to work in more adverse weather conditions than current similar average cutter suction dredgers.

With more than 151m of Willem van Rubroeck, we are once again pushing our own boundaries. It is the company's willpower to do things our way. To go one step further every time. To improve our own fleet and to create a market for it. Until recently, J.F.J. De Nul was the largest cutter suction dredger in our fleet, but Willem van Rubroeck can now boast this title. The new cutter has more cabins, a longer cutter ladder and a larger total installed power.

Doing things our way

Renaat Lebon

Fleet Coordinator

“We are again taking big steps forward in terms of size of scale, weather resistance and power. It’s in our DNA to keep pushing our limits”

Ruben De Lille

Process Engineer

“When our spud carrier pitch and roll compensation is activated, we measure significant less forces on our main spud, resulting in a higher workability in adverse weather.”

Patrick Visbeen

Captain

“We are now continuing where other vessels have to stop. Neither swells, nor hard surfaces can stop her, as she has already proven during projects in Mauritania.”

Wondering what the Willem van Rubroeck looks like on the inside?

The spud carrier traveling cylinder was given a dynamic and active component. Meaning that the work spud in the spud carrier is suspended by shock absorbers. When the force on the spud becomes too great, the shock absorbers will protect the spuds from being overloaded.

The start of its career in Mauritania

So, we built the Willem van Rubroeck. The performance of this cutter suction dredger of substantial size is still conditioned by weather conditions, but thanks to innovative adjustments, the vessel can dredge on higher swells and on harder subsoil. Its maiden dredging project took place in Mauritania and immediately proved the added value of the new features on a turbulent Atlantic Ocean.

Cutter suction dredgers cannot execute works in challenging weather conditions. Since they are extremely weather-sensitive, the vessel must maintain its exact position at all times. Unexpected sea conditions can disturb the entire planning of a project – and impact your budget.

Willem van Rubroeck's cutter ladder can reach a depth of 38 m, but with an attachment, it can dredge to an exceptional depth of 45 m.

Every achievement of the Willem van Rubroeck is the work of a strong team. Prior to a project, our engineers carry out structural and environmental studies. Geologists investigate the hardness of the soil on location, based on a soil survey on site or through results provided by previous works.

The planning of a project and the work done by the ship and its crew are very dependent on the weather conditions. Therefore, at the beginning of the project, the operational superintendent studies the average weather and the long-term averages of the waves. This way, we estimate which period is the most suitable to start working. On board, we use a waverider, which is a buoy that floats on the water and measures the height of the waves. These measurements give an idea of how correct the predictions are, and also make them more accurate. With that accurate model, the rest of the work can be planned better.

The cutter suction dredger started her very first assignments in Mauritania. In the port of the capital Nouakchott, the vessel is working for developer ARISE Mauritania to deepen the access channel, the port basin and the newly constructed berth alongside for the Nouakchott Container Terminal.

During the summer months, Willem van Rubroeck did a layover in Nouadhibou to dredge rock banks in the 26-kilometre-long access channel for the ‘Société Nationale Industriëlle et Minière’ (SNIM).

Willem van Rubroeck was immediately thrown to the lions and her capabilities were put to the test, which she passed with flying colours. We were able to test her workability in adverse weather conditions and she overcame the combination of high and long swells while easily precutting the remaining hard soil.

The human touch

Of course, the vessel is not just 'bigger'. Thanks to these upscaling measures, the cutter is also a lot more powerful and therefore able to dredge in very hard rocky subsoil. This vessel gets its extra power from the combination of its large cutter capacity, its heavy cutter ladder weight and the strong pulling anchor wires.

The cutter ladder can move up and down with the help of two winches. On most cutters the ladder is attached through a wire to a fixed component on the vessel: the ladder gantry. Here, the ladder suspension rests on an air cushions. Vibrations are absorbed by these air cushions, reducing the risk of damage to the vessel and increasing the comfort on board.

Ain’t no wave high enough

Impossible made possible

With more than 151m of Willem van Rubroeck, we are once again pushing our own boundaries. It is the company's willpower to do things our way. To go one step further every time. To improve our own fleet and to create a market for it. Until recently, J.F.J. De Nul was the largest cutter suction dredger in our fleet, but Willem van Rubroeck can now boast this title. The new cutter has more cabins, a longer cutter ladder and a larger total installed power.

Doing things our way

So, we built the Willem van Rubroeck. The performance of this cutter suction dredger of substantial size is still conditioned by weather conditions, but thanks to innovative adjustments, the vessel can dredge on higher swells and on harder subsoil. Its maiden dredging project took place in Mauritania and immediately proved the added value of the new features on a turbulent Atlantic Ocean.

Cutter suction dredgers cannot execute works in challenging weather conditions. Since they are extremely weather-sensitive, the vessel must maintain its exact position at all times. Unexpected sea conditions can disturb the entire planning of a project – and impact your budget.

More details?

Check out our project summary.

Wondering what the Willem van Rubroeck looks like on the inside?

The cutter suction dredger started her very first assignments in Mauritania. In the port of the capital Nouakchott, the vessel is working for developer ARISE Mauritania to deepen the access channel, the port basin and the newly constructed berth alongside for the Nouakchott Container Terminal.

During the summer months, Willem van Rubroeck did a layover in Nouadhibou to dredge rock banks in the 26-kilometre-long access channel for the ‘Société Nationale Industriëlle et Minière’ (SNIM).

Willem van Rubroeck was immediately thrown to the lions and her capabilities were put to the test, which she passed with flying colours. We were able to test her workability in adverse weather conditions and she overcame the combination of high and long swells while easily precutting the remaining hard soil.

The start of its career in Mauritania

Ruben De Lille

Process Engineer

“When our spud carrier pitch and roll compensation is activated, we measure significant less forces on our main spud, resulting in a higher workability in adverse weather.”

Patrick Visbeen

Captain

“We are now continuing where other vessels have to stop. Neither swells, nor hard surfaces can stop her, as she has already proven during projects in Mauritania.”

Renaat Lebon

Fleet Coordinator

“We are again taking big steps forward in terms of size of scale, weather resistance and power. It’s in our DNA to keep pushing our limits”

Every achievement of the Willem van Rubroeck is the work of a strong team. Prior to a project, our engineers carry out structural and environmental studies. Geologists investigate the hardness of the soil on location, based on a soil survey on site or through results provided by previous works.

The planning of a project and the work done by the ship and its crew are very dependent on the weather conditions. Therefore, at the beginning of the project, the operational superintendent studies the average weather and the long-term averages of the waves. This way, we estimate which period is the most suitable to start working. On board, we use a waverider, which is a buoy that floats on the water and measures the height of the waves. These measurements give an idea of how correct the predictions are, and also make them more accurate. With that accurate model, the rest of the work can be planned better.

The human touch

Willem van Rubroeck's cutter ladder can reach a depth of 38 m, but with an attachment, it can dredge to an exceptional depth of 45 m.

The cutter ladder can move up and down with the help of two winches. On most cutters the ladder is attached through a wire to a fixed component on the vessel: the ladder gantry. Here, the ladder suspension rests on an air cushions. Vibrations are absorbed by these air cushions, reducing the risk of damage to the vessel and increasing the comfort on board.

The spud carrier traveling cylinder was given a dynamic and active component. Meaning that the work spud in the spud carrier is suspended by shock absorbers. When the force on the spud becomes too great, the shock absorbers will protect the spuds from being overloaded.

In the event of higher swells or waves, dredging works with a cutter are negatively affected, because the spud and the cutterhead have to remain in the same position at all times. By making some unique adjustments to the spud carrier and the flexible suspension of the cutter ladder of the Willem van Rubroeck, we ensured that more movements on the vessel’s structure are allowed and vibrations are absorbed, so that it can continue to work in more adverse weather conditions than current similar average cutter suction dredgers.

Ain’t no wave high enough

Of course, the vessel is not just 'bigger'. Thanks to these upscaling measures, the cutter is also a lot more powerful and therefore able to dredge in very hard rocky subsoil. This vessel gets its extra power from the combination of its large cutter capacity, its heavy cutter ladder weight and the strong pulling anchor wires.