Five decades of improved technology:

What has changed?

The purchase of the Sanderus in 1967 is a milestone in our company history. This trailing suction hopper dredger with a capacity of 5,000 m³ enabled us to expand our business all over the world. In 2016, the vessel retired. But in 2019, we built a new Sanderus with improved technology. What has changed on board in 52 years?

"The old Sanderus had 2 suction pipes. The basic drag head offered fewer possibilities, which made it difficult to determine how far we were operating from the vessel."

"Today, our vessels are equipped with the latest navigational technology."

"In his well equipped galley, the chef

prepares culinary feasts."

"The crew enjoys soundproof and air conditioned facilities."

"The crew shared all sanitary installations, only the captain had a toilet in his cabin."

"Our mess consisted of some tables and chairs."

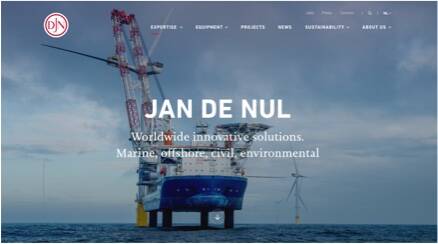

Sustainable, versatile and tailor-made. Jan De Nul Group continuously invests in a modern fleet, equipped with state-of-the-art technology. If it doesn’t exist, we design and develop the technology ourselves. Interested in the technical possibilities our fleet has to offer?

"In the early days, the facilities on board were quite plain."

"On each side of the ‘hopper’ 12 hydraulic bottom doors unloaded the dredged material. The impressive supporting construction turned maintenance works into a real challenge."

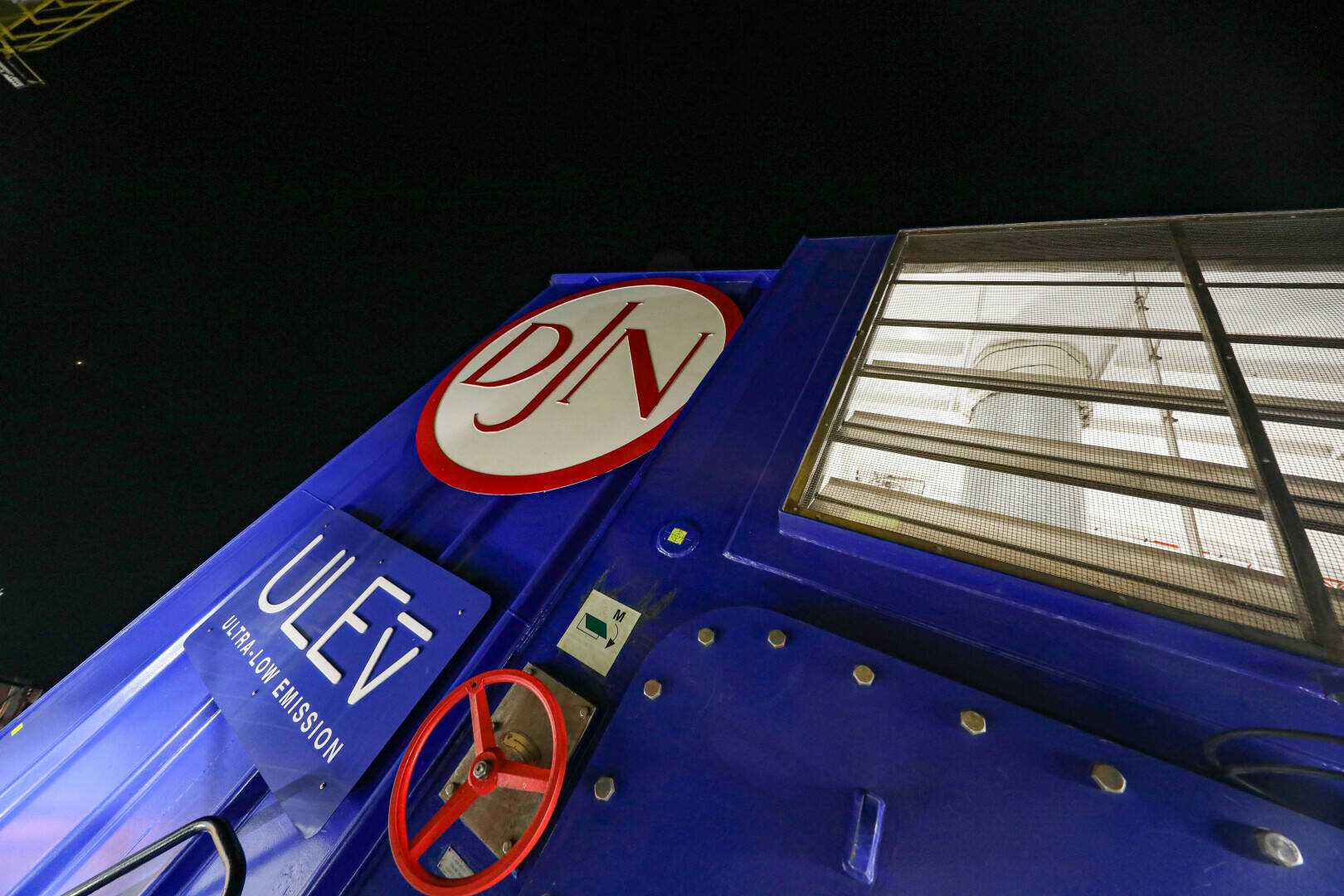

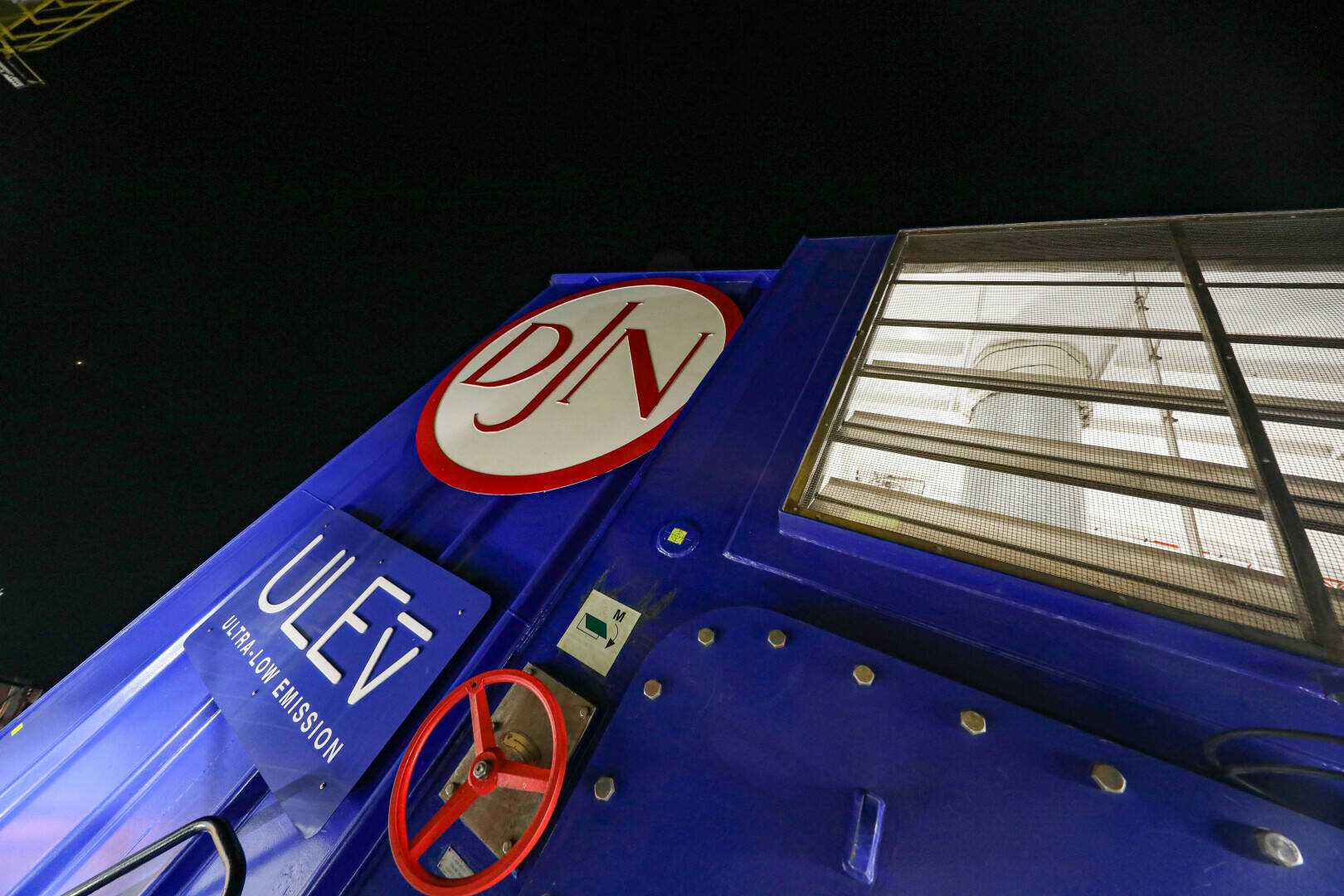

JAN DE NUL VESSELS FIRST TO RECEIVE NEW BUREAU VERITAS ULTRA-LOW EMISSIONS NOTATION

The most eye-catching technological improvement of the past five decades is the ULEv technology on board of the Sanderus. Our new Sanderus is an Ultra-Low Emission vessel equipped with a state-of-the-art exhaust gas treatment system: a catalyst renders nitrogen oxides harmless whereas a soot filter blocks the tiniest particles.

Bureau Veritas (BV), world leader in testing, inspection, and certification, has developed a new notation to recognize the performance of ultra-low emission vessels (ULEvs). Jan De Nul Group’s newest Trailing Suction Hopper Dredgers, Sanderus, Ortelius, Tristão Da Cunha, Afonso De Albuquerque, Diogo Cão have now become the very first vessels worldwide to receive this recognition.

Read more about Bureau Veritas supporting our sustainability journey.

At this moment, our Sanderus is performing maintenance dredging works in the Port of Zeebrugge, Belgium. Find out more about this project.

"The new Sanderus has 4 bottom doors, controlled by 1 central cylinder. This vessel can also deposit dredged material in shallow water, using pre-unload doors. We can also pump the material ashore or reclaim land using the rainbowing technique."

"In the early days, the facilities on board were quite rudimentary."

"The bridge and the engine room communicated with a telegraph."

Etienne Baert

Technical Superintendent since 1975

"Today, our vessels are equipped with the latest navigational technology."

"After work, the crew can relax at the bar, in the gym or in the television corner."

Raf Quintelier

Senior Superintendent Vessel Construction since 2007

"The new Sanderus only has one suction pipe. The drag head operates according to pre-installed parameters. This enables us to dredge more accurately."

Hydraulic bottom doors

"The navigational equipment on board was not as sophisticated as today. With nautical charts and buoys, we calculated the position of the vessel during dredging. The bridge and the engine room communicated through means of a telegraph."

"Today, our vessels are equipped with the latest navigational technology. Since all systems are integrated, we can work more accurately. Two electrically driven rudder propellers and a bow thruster make the vessel easily manoeuvrable, even at low speed."

Bottom doors, controlled by one central cylinder

Five decades of improved technology:

What has changed?

The purchase of the Sanderus in 1967 is a milestone in our company history. This trailing suction hopper dredger with a capacity of 5,000 m³ enabled us to expand our business all over the world. In 2016, the vessel retired. But in 2019, we built a new Sanderus with improved technology. What has changed on board in 52 years?

"After work, the crew can relax at the bar, in the gym or in the television corner."

Raf Quintelier

Senior Superintendent Vessel Construction since 2007

Orsi Academy

Orsi Academy

on Marine & Offshore Division projects decreased by a factor 5 over a period of 6 years.

"The bridge and the engine room communicated with a telegraph."

Etienne Baert

Technical Superintendent since 1975

"The crew shared all sanitary installations, only the captain had a toilet in his cabin."

"Our mess consisted of some tables and chairs."

JAN DE NUL VESSELS FIRST TO RECEIVE NEW BUREAU VERITAS ULTRA-LOW EMISSIONS NOTATION

The most eye-catching technological improvement of the past five decades is the ULEv technology on board of the Sanderus. Our new Sanderus is an Ultra-Low Emission vessel equipped with a state-of-the-art exhaust gas treatment system: a catalyst renders nitrogen oxides harmless whereas a soot filter blocks the tiniest particles.

Bureau Veritas (BV), world leader in testing, inspection, and certification, has developed a new notation to recognize the performance of ultra-low emission vessels (ULEvs). Jan De Nul Group’s newest Trailing Suction Hopper Dredgers, Sanderus, Ortelius, Tristão Da Cunha, Afonso De Albuquerque, Diogo Cão have now become the very first vessels worldwide to receive this recognition.

Read more about Bureau Veritas supporting our sustainability journey.

"In his well equipped galley, the chef

prepares culinary feasts."

"The crew enjoys soundproof and air conditioned facilities."

"The old Sanderus had 2 suction pipes. The basic drag head offered fewer possibilities, which made it difficult to determine how far we were operating from the vessel."

"The new Sanderus only has one suction pipe. The drag head operates according to pre-installed parameters. This enables us to dredge more accurately."

Bottom doors, controlled by one central cylinder

Hydraulic bottom doors

"The new Sanderus has 4 bottom doors, controlled by 1 central cylinder. This vessel can also deposit dredged material in shallow water, using pre-unload doors. We can also pump the material ashore or reclaim land using the rainbowing technique."

"On each side of the ‘hopper’ 12 hydraulic bottom doors unloaded the dredged material. The impressive supporting construction turned maintenance works into a real challenge."

Sustainable, versatile and tailor-made. Jan De Nul Group continuously invests in a modern fleet, equipped with state-of-the-art technology. If it doesn’t exist, we design and develop the technology ourselves. Interested in the technical possibilities our fleet has to offer?

"The navigational equipment on board was not as sophisticated as today. With nautical charts and buoys, we calculated the position of the vessel during dredging. The bridge and the engine room communicated through means of a telegraph."

"Today, our vessels are equipped with the latest navigational technology. Since all systems are integrated, we can work more accurately. Two electrically driven rudder propellers and a bow thruster make the vessel easily manoeuvrable, even at low speed."